Dual-focus laser welding technology

Laser welding is becoming one of the main means of improving the quality and efficiency of the automobile main engine factory and reducing environmental pressure. What are the most demanding laser processing technologies? Which technologies are these processes focused on? What are the main features of the processing tools used in these processes?

From the perspective of environmental protection, as the global climate changes, automobile exhaust emissions, consumption of petroleum energy and other factors force the OEM to continuously improve the process to cope with the increasingly severe environmental and energy pressure! Especially the lightweight structure of automobiles is currently the most mainstream development trend.Most common automotive lightweight processing methods include load-adaptive and lightweight components made of steel-aluminum blending, die-casting, stamping and stamping.

Dual-focus laser welding process and advantages

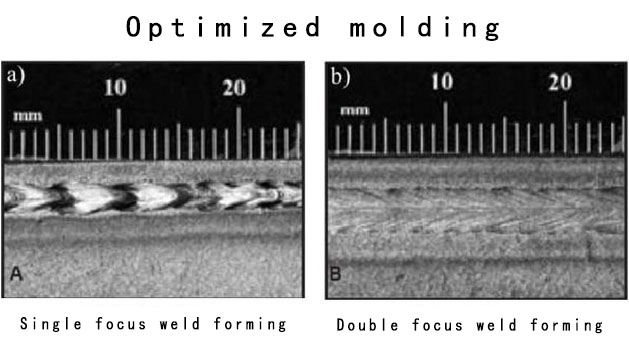

A laser beam can be desperated into two beams by an optical lens, by adjusting the energy density, spacing and facula, the process can be optimized to meet a high quality welding.Double focus welding can effectively improve the gap adaptability, reduce welding defects and improve the welding quality of unequal thick plates and different materials.

Features

Take 4mm thick 6061 aluminum alloy welding as an example: welding power 4KW, welding speed 3m/min

Different facula and energy distribution influence welding molding.Choose the appropriate facula and energy ratio to effectively improve the molding effect basing on the material and welding process!

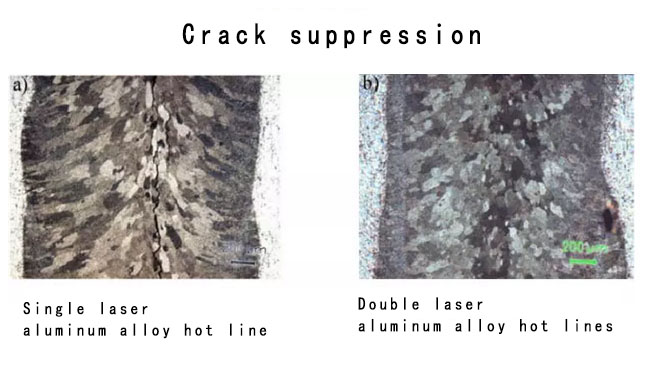

Dual-focus laser can improve the welding thermal loop, so it can refine welding structure and inhibit crack growth!

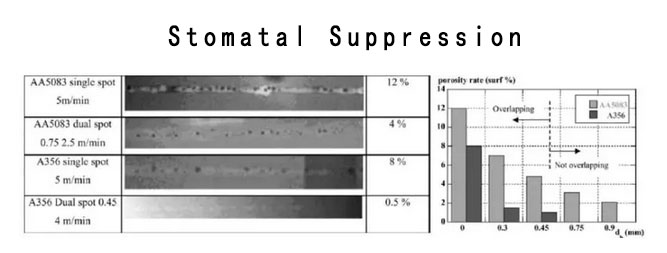

Dual-focus laser improve the stability of the keyhold, which reduces the generation of air holes!

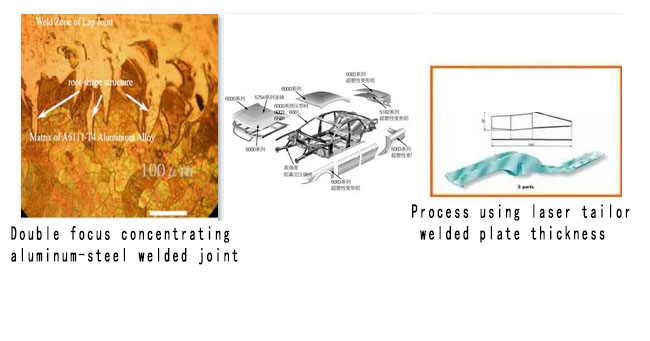

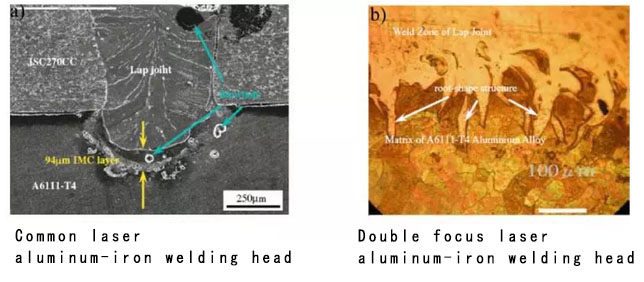

Dissimilar Metal - Aluminum - Steel Welding

As a common technology for lightweight vehicles, lightweight steel-aluminum composite parts are ideal for reducing vehicle weight, which in turn can help reduce pollutant emissions.By using bifocal laser welding, changing the facula energy ratio can effectively improve the welding effect of dissimilar metals.

Double molten pool unequal thick plate laser tailor welding

In our car, many parts such as the inner door panel, the B-pillar, the longitudinal beam and the front wall are stamped by the blank welded plate, which not only improves the strength of the body but also reduces the fuel economy.Double-focus welding can effectively improve the welding effect of unequal thickness materials by changing the facula distribution and the facula energy ratio.

Laser head product introduction

- Dual-focus distance adjustment range: 0-10mm

- Energy distribution adjustment range: 23%: 77% - 77%: 23%

- Focus rotation range: ±360°