Feature of Laser Welding

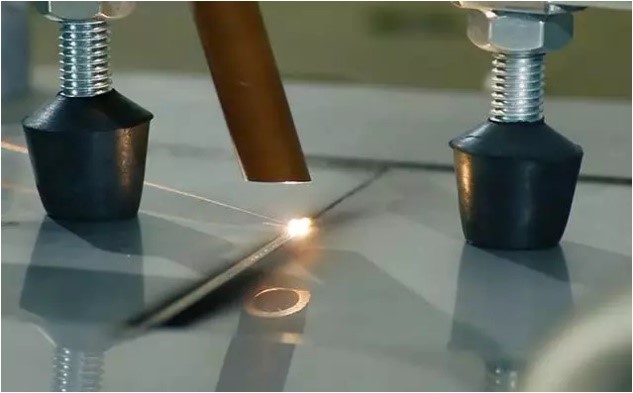

Laser welding is illuminating high-density laser beam at the workpieces connection, the workpieces melted quickly and form molten pool after absorbing laser energy, then solidfy and join together in approach cooling process.

The features in compare of other welding technology:

- High speed, deep depth, small deformation.

- Simple equipment; can operate welding process in conservatory or special conditions. For example, laser beam won’t shift when laser through electromagnetic field; operation can be carried out in vacuum, air, or some sort of gas environment

- Heat-resisting materials can be welded such as titanium and quartz. Dissimilar material welding can make great effect.

- After laser focused, power density is high; when operate high power welding, depth to width ratio 5:1 and up to 10:1

- Micro-weld can be operated. When laser beam focused speckle is tiny, accurate positioning, and able to apply to batch automation production in micro assembly weld.

- Laser can weld the unapproachable parts, conducting non-contact distance welding and have high activation.

- Laser beam is easily achieved and separated by time and space, it can operate multi-beam process and multi-position process which provide more precision welding conditions.

The arc welding, oxygen welding, resistance welding or soldering have some deficiencies, relatively, laser welding has some limitations.

- Laser welding workpiece position should be quite accurate in laser beam focus area.

- Laser welding is limited by the thickness, the workpiece thickness over 19mm is unsuitable for laser welding.

- High-reflective and high thermal conductivity such as copper and alloy, weldability is affected by workpiece material.

- When operate high-power and medium-power laser welding, ionized gas should be eliminated in used of plasma generator to ensure the weld pass is not appeared.

- Weld pass is quick solidified, it may have air hole and embrittlement, wall-plug efficiency is too low and usually down to 10%.

Laser cutting is high-precision and high-efficiency, wide cutting range and high process ability. Usually applied to automobile industry and material process. Laser cutting process has some problems which simply and deadly.