Fiber laser welding system can increase processing rate.

Like no other time before, laser processing reduces expenditure of welding materials and joint different materials with high power laser.

There’s no need to spend much time to training, and it’s easy to operate.It's an indispensable system which greatly enhances the quality and processing rate in recent industry.

Laser metal welding application is quite extensive, We can choose laser and welding head according to different materials, thickness and application requirements.

- Copper and aluminum materials reflection is relatively higher than 1064nm wavelength laser, so we choose high-power laser; Stainless materials reflection is lower so we choose low-power laser.

- Thickness is depended on laser power, the higher power, the higher efficiency.

- Use pulsed mode in certain application.

左右滑動看表格

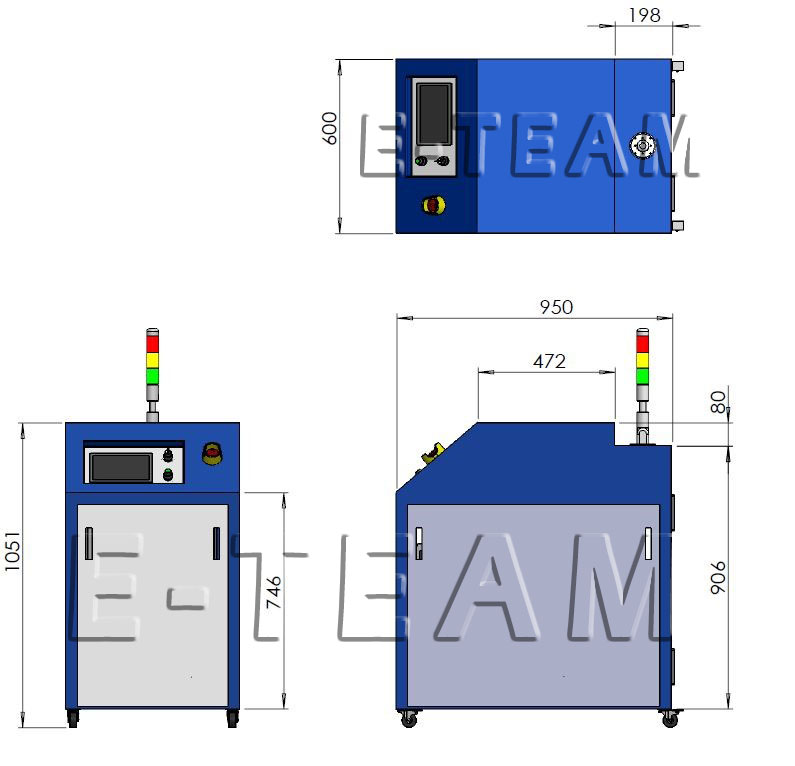

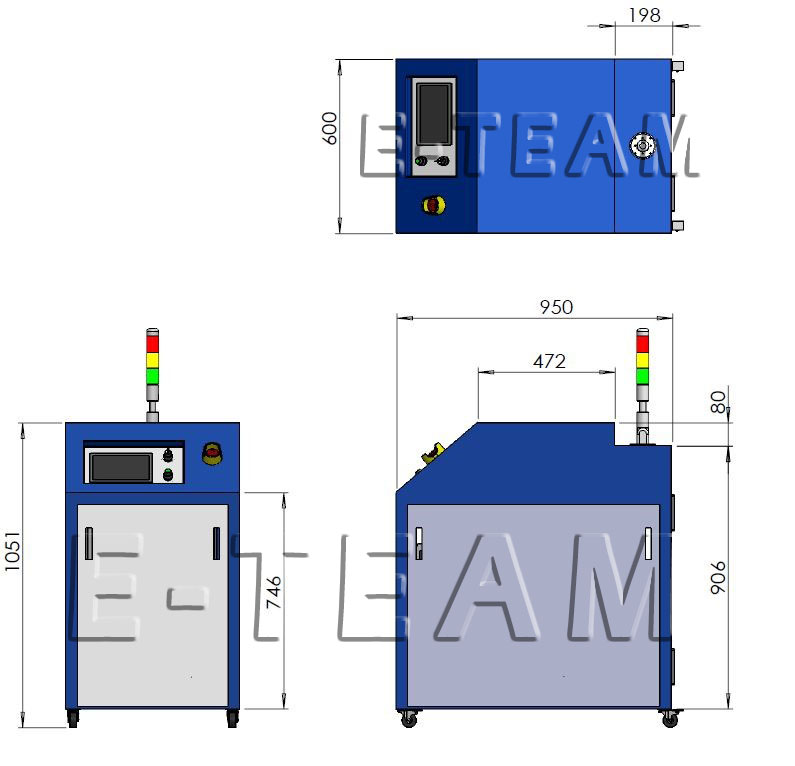

左右滑動看表格| Size(mm) | L: 950 W:600 H:1051(Including wheels) |

Guide laser | red guide laser |

| Voltage | Single phase 220V | Output fiber | 5m |

| Power consumption | 6Kw | Assist/Gas shield | coaxial |

| Operation mode | 2 Fiber laser modules(single-module 250W)CW | Collimated focal length | Selective |

| Emission wavelength | 1070nm | Focal length | Selective |

| Output fiber termination | QBH-compatible connector | Cooling method | Forced air |

Fiber laser welding system can increase processing rate.

Like no other time before, laser processing reduces expenditure of welding materials and joint different materials with high power laser.

There’s no need to spend much time to training, and it’s easy to operate.It's an indispensable system which greatly enhances the quality and processing rate in recent industry.

Laser metal welding application is quite extensive, We can choose laser and welding head according to different materials, thickness and application requirements.

- Copper and aluminum materials reflection is relatively higher than 1064nm wavelength laser, so we choose high-power laser; Stainless materials reflection is lower so we choose low-power laser.

- Thickness is depended on laser power, the higher power, the higher efficiency.

- Use pulsed mode in certain application.

左右滑動看表格

左右滑動看表格| Size(mm) | L: 950 W:600 H:1051(Including wheels) |

Guide laser | red guide laser |

| Voltage | Single phase 220V | Output fiber | 5m |

| Power consumption | 6Kw | Assist/Gas shield | coaxial |

| Operation mode | 2 Fiber laser modules(single-module 250W)CW | Collimated focal length | Selective |

| Emission wavelength | 1070nm | Focal length | Selective |

| Output fiber termination | QBH-compatible connector | Cooling method | Forced air |