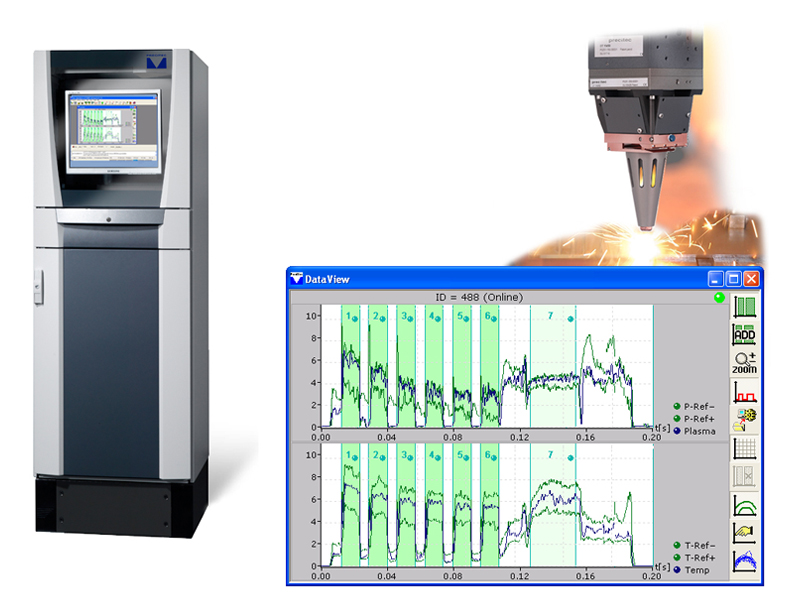

Laser Welding Monitor LWM

The Laser Welding Monitor (LWM) is a real-time monitoring system for series production and it provides online quality-relevant information about laser welding seam. It detects changes to welding parameters, deviations in the welding joint and lack of fusion. The welding process finger print is determined via the reference values of the plasma, metal vapor, temperature or laser radiation and compared to running production signals and transferred in real time.

- In-process monitoring system for solid-state, diode and CO2 lasers.

- Self-sufficient real time measuring system.

- Suitable for various welding processes (keyhole welding, heat conduction welding, pulse, CW laser).

- Provides exposure about welding depth, seam position, pores, splashes etc. in connection with the welding process.

- Provides established process and possible error correction.

- Contact-free signal recording and evaluation methods in line with the process.

- Number of digital inputs / outputs : 16 each

- Number of programs / expanded to : 32/128 to 256

- Number of parallel processing data channels : max. 8

- Number of detectors : max. 16

- Sample rate of detectors : max. 40 kHz

The Laser Welding Monitor (LWM) is a real-time monitoring system for series production and it provides online quality-relevant information about laser welding seam. It detects changes to welding parameters, deviations in the welding joint and lack of fusion. The welding process finger print is determined via the reference values of the plasma, metal vapor, temperature or laser radiation and compared to running production signals and transferred in real time.

- In-process monitoring system for solid-state, diode and CO2 lasers.

- Self-sufficient real time measuring system.

- Suitable for various welding processes (keyhole welding, heat conduction welding, pulse, CW laser).

- Provides exposure about welding depth, seam position, pores, splashes etc. in connection with the welding process.

- Provides established process and possible error correction.

- Contact-free signal recording and evaluation methods in line with the process.

- Number of digital inputs / outputs : 16 each

- Number of programs / expanded to : 32/128 to 256

- Number of parallel processing data channels : max. 8

- Number of detectors : max. 16

- Sample rate of detectors : max. 40 kHz