LIGHTWELDTM 1500

Handheld Laser Welding System

Swift for more

Swift for more| QUICK SPECS LASER POWER HIGH PEAK POWER Up to 1500 W Up to 2500 W SINGLE SIDED WELD THICKNESS Stainless Steel, Galvanized Steel, Mild Steel and Aluminum: Up to 4 mm Copper: Up to 1mm |

INCLUDE:

|

APPLICATIONS:

|

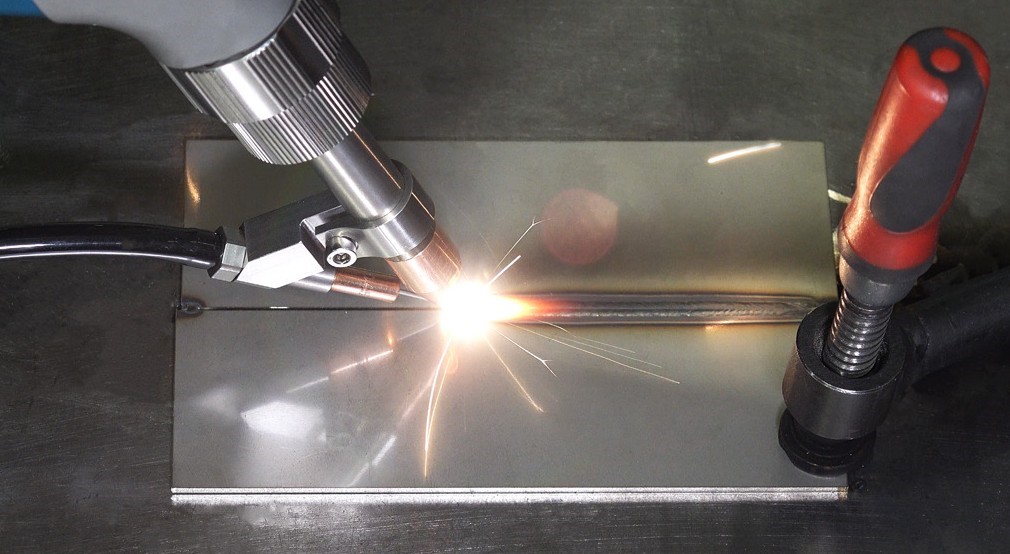

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality,consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion,undercut or burn-through. The heat affected zone is dramatically minimized, as is the need for traditionalpost-processing grinding or polishing for increased productivity, less scrap and lower cost-per-part.

Swift for more

Swift for more| LightWELD Laser Welding | |

| High Speed | Up to 4X Faster than traditional methods - increased productivity for lower costs-per-part |

| High Quality | Consistent welding of thick, thin and reflective metals without distortion, undercut or burn-through - minimal heat affected zone |

| Easy to Use | Simple set up, easy to learn and operate for consistent high-quality welds |

| Enhanced Material Capability | Metals with dissimilar thicknesses, ultra-thin parts, copper welding, materials with low and high electrical conductivity |

| Wobble Welding | Up to 5 mm of additional weld width - increases capability and creates highly aesthetic seams |

| Operator Safety | Multi-level sensors and interlock safety features |

Swift for more

Swift for more| Laser Power | High Peak Power | Power | Mode Storage Capacity | Wobble Length | Wobble Frequency | Dimensions LxWxH | Weight |

| Up to 1500W | Up to 2500W | 220V Single Phase, 24 A | 74 | Up to 5 mm | Up to 300 Hz | 641 x 316 x 534 mm 25.2” x 12.4” x 21” |

53 kg 118 lbs |

SAFETY FEATURES:

LightWELD is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

BUILT-IN FEATURES INCLUDE:

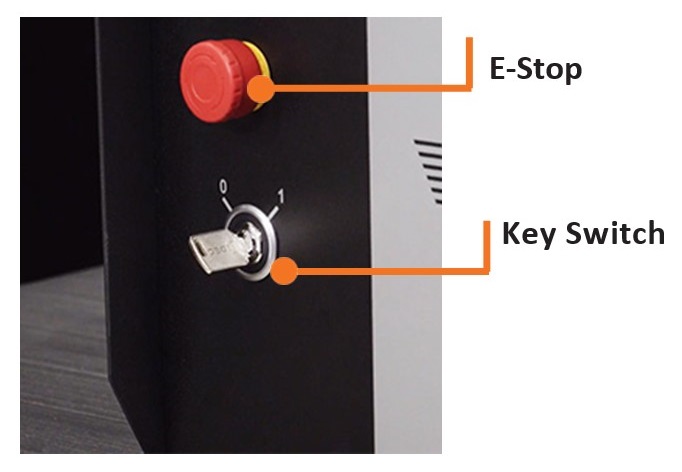

- Key switch control of laser source and Emergency-stopbutton ensure deliberate operation

- Fiber laser interlock verifies integrity of laser deliveryto the welding gun

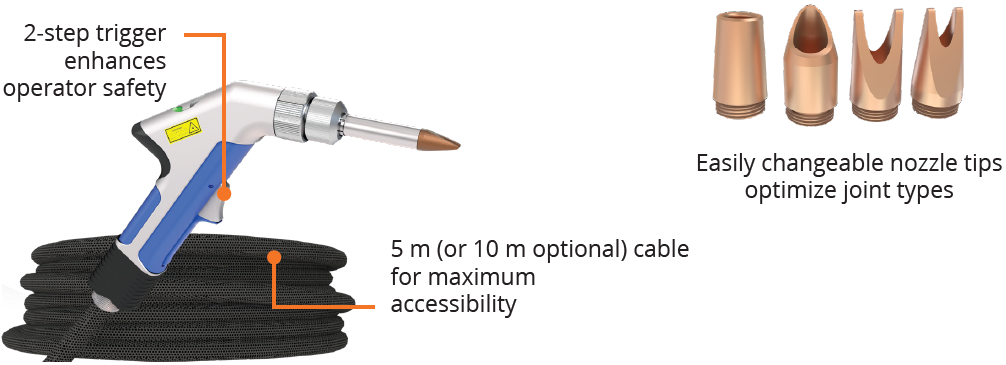

- 2-step weld gun trigger, enable and then fire, forintentional operation

- Part contact electrical interlock turns off the laser powerif the welding head is not in contact with the welded parts

Operators must wear all recommended personal protective equipment (PPE), including the IPG laser safety glassesand IPG helmet with shield provided with LightWELD™, laser-resistant and heat resistant gloves, caps, leather apronand other laser-resistant and heat-resistant clothing.

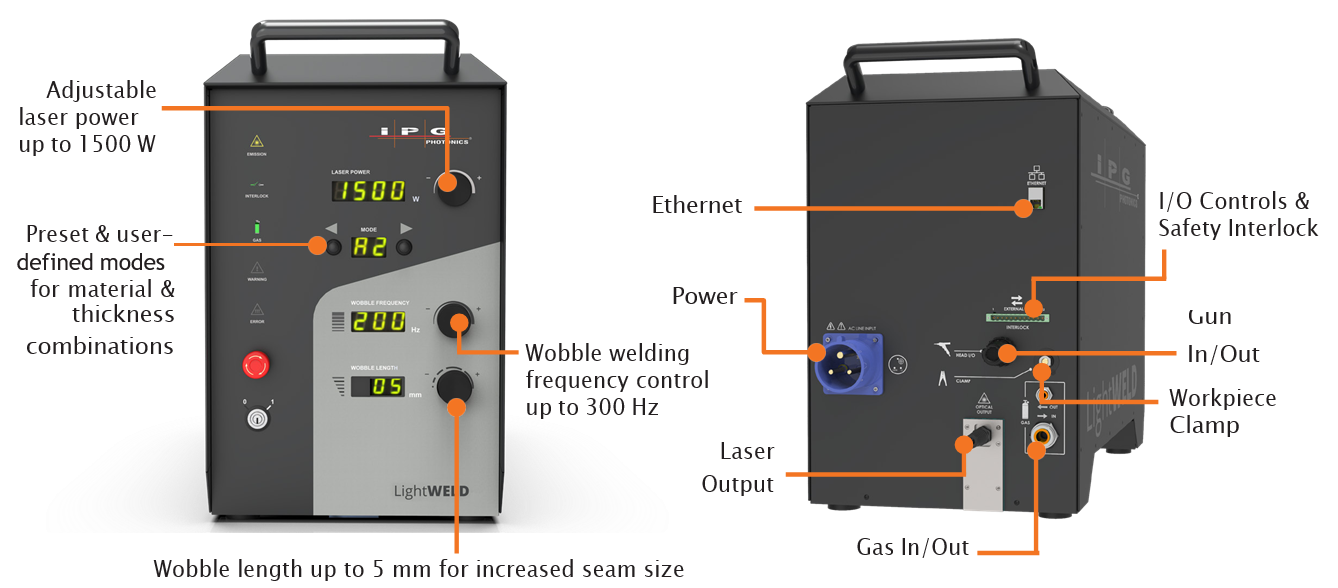

CONTROL PANEL AND CONNECTIONS:

Laser power up to 1500 W is easily adjusted with intuitive controls to quickly dial in optimum weld settings for various materials and thicknesses. With 74 stored preset and user-defined process parameters, novice welders can be trained and welding in a matter of hours. Select stored modes provide up to 2500 W of high peak power for even greater welding capability.

Clearly labeled rear connections make getting started fast and easy. Laser delivery, gas and gun control is pre-wired in a 5 m (optional 10 m) cable. Just plug in the power cord and gas connection, attach the clamp to your worksurface and you are ready to go. An ethernet connection provides access to advanced parameter settings to fine tune and save process parameters.

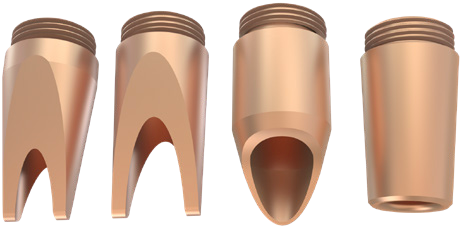

HANDHELD GUN & NOZZLE TIPS:

The handheld welding gun is compact, ergonomic and proven to be the most comfortable, well balanced and easyto use gun available with a selection of nozzle tips to optimize different joint types. The light weight and built-inwobble functionality enables operators to produce high-quality welds consistently throughout the day and safelywith its 2-step trigger.

ACCESSORIES

LIGHTWELDTM WIRE FEEDER PACKAGE

P/N: CEU00003548XXXXU

This optional Wire Feeder package includes all necessaryhardware and software to add a wire weldingcapability to the LightWELD handheld Laser Welder.

Included with Wire Feeder Kit:

- Wire Feed Unit

- Proprietary Weld Head Nozzle Attachment

- System Trigger Cable

- 4 tips: 0.8mm, 0.9mm, 1.2mm, 1.6mm

- 4 Rollers (2 U-Rollers, 2 V-Rollers)

- 4 Liners (2 Teflon liners, 2 Steel liners)

- IPG Process Mode software upgrade

- Used for manual laser wire welding of low carbon steel,stainless steel, aluminum, non-ferrous metals and other alloys

- LightWELD provides synchronization trigger signal to wire feedunit. Wire feed settings adjusted on the wire feed unit

- Wire feeder nozzle attachment guides wire precisely to theweld pool

- LightWELD Process Modes provide standard LightWELD parameter settings for typical materials and wire types

Swift for more

Swift for more| LightWELD Wire Feeder Specifications | |

| Wire feed delivery length | 2.7 m (9 ft) |

| LightWELD Interface | Low Voltage enable signal cable |

| Wire Feed Speed Range | 40 – 600 cm/min (15 - 230 ipm) |

| Compatible Wire Diameters | 0.8 mm - 1.6mm |

| Wire Reel Capacity | 1 kg (2 lb), 5 kg (10 lb) or 10 kg (25 lb) by shaft change |

| Compatible Wire Materials | Steel, Stainless Steel, Aluminum |

| Power Requirements | 115V 50/60 Hz |

| Wire Feed Unit Weight | 22 kg (48.4 lb) |

| Wire Feed Unit Dimensions (L X W X H) | 420 mm (16.5 in.) x 210 mm (8.3 in.) x 570 mm (22.4 in.) |

LIGHTWELDTM WIRE CABINET

P/N: CEU00003073XXXXU

This heavy duty welding cabinet provides mobility for your LightWELD laser welding system and accessories.

KEY FEATURES INCLUDE:

- Top platform sized for LightWELD baseunit & optional wire feeder

- Three storage drawers with ball bearing slides

- Cabinet for helmet storage

- Locking cabinet with adjustable shelves

- Platform & tether chains for two 225 mm (9 in) gas cylinders

- Cable hooks for LightWELD to Head umbilical

- Lockable swivel castors

Swift for more

Swift for more| LightWELD Welding Cabinet Size | Weight Capacity | |

| Cart (L x W x H) | 1238 mm (48.75 in.) x 648 mm (25.5 in.) x 850 mm (33.5 in.) | |

| Weight | 73.2 kg (161.3 lb) | |

| Top Surface (L x W x H) | 875 mm (34.5 in W) x 515 mm (20.3 in L) | 72.6 kg (160 lb) |

| Drawer 1 (L x W x H) | 410 mm (16.3 in) x 320 mm (12.7 in) x 32 mm (1.3 in) | 18.1 kg (40 lb) |

| Drawer 2 & 3 (L x W x H) | 410 mm (16.3 in) x 320 mm (12.7 in) x 115 mm (4.5 in) | 36.2 (80 lb) each |

| Helmet Cabinet (L x W) | 495 mm (19.5 in) x 355 m (14 in) | 18.1 kg (40 lb) |

| Cylinder Platform | Up to two 225 mm (9 in) gas cylinders | |

ACCESSORIES

LIGHTWELDTM PPE & CONSUMABLES

Handheld Laser Welding System

Welding Helmet with Shield

CEU00002506XXXXU

Auto-Darkening LaserWelding Helmet with IR Shield & IR coated lens provides protection from specular reflections

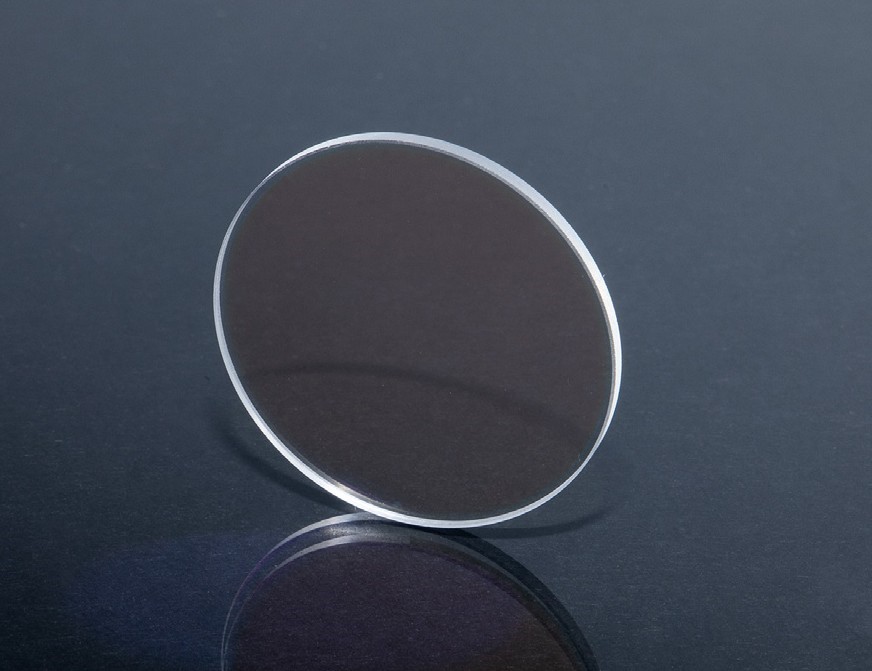

Cover Slides

CDSBOM00023702XU

Pack of 20

Safety Glasses

CMMIXXX0002678PX

w/ Side Shield Protection

1000-1550 nm OD 7+

Safety Glasses LFO

CMMIXXX0002677PX

Large Fit Over

1000-1550 nm OD 7+

Safety Glasses ADJ

CMMIXXX0002679PX

Adjustable temple bar

1000-1550nm OD7+

左右滑動看表格

左右滑動看表格 Copper nozzle tip Set of 4 CDSBME000089XXXU |

1 point CMUS0008398XXXXU |

2 point 6mm CMUS0008411XXXXU |

2 point 9mm CMUS0008719XXXXU |

Cone CMUS0008794100XU |

左右滑動看表格

左右滑動看表格 AI 1100 Nozzle tip Set of 4 CDSBME00008901XU |

1 point CMUS0009402XXXXU |

2 point 6mm CMUS0009401XXXXU |

2 point 9mm CMUS0009400XXXXU |

Cone CMUS0009399XXXXU |

Video

LightWELD 1500 High Speed Welding